- ISO 9001:2015 Certified Company

- +91-9672985402

- info@vasundharamicron.com

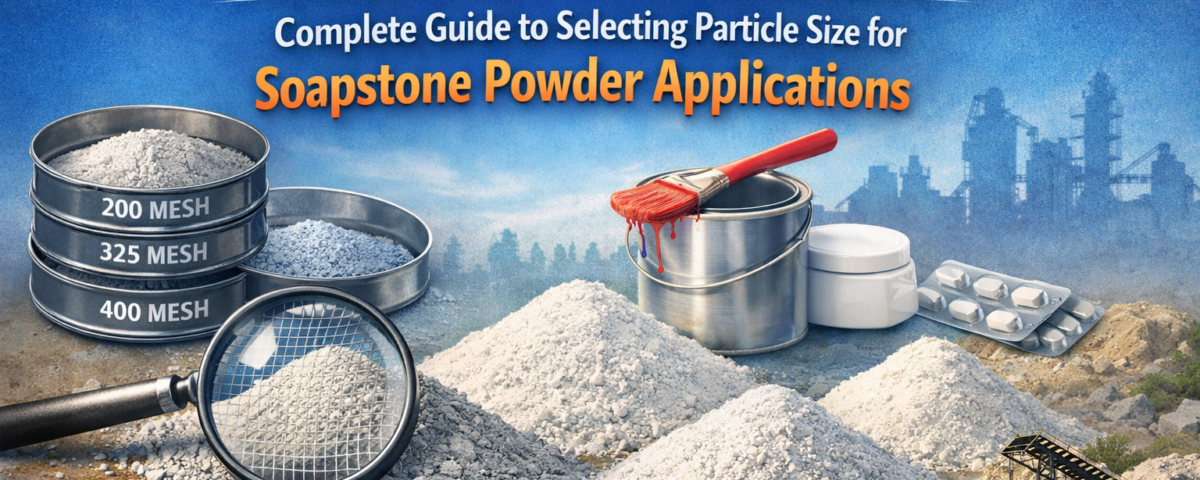

Mesh Size Matters: Complete Guide to Selecting Particle Size for Soapstone Powder Applications

How Responsible Talc Powder Manufacturers in India Reduce Environmental Impact

January 12, 2026Here's a mistake that cost one paint manufacturer ₹8 lakhs: ordering 200 mesh when they needed 400 mesh. The result? Gritty finish, rejected batches, and angry clients. As a soapstone powder supplier in India with 66+ years of experience, we see this happen more often than it should. The good news? Choosing the right mesh size is straightforward once you know what matters. Let's make sure you get it right the first time.

Let's talk about getting it right the first time.

What Exactly Is Mesh Size (And Why Should You Care)?

Think of mesh size as a sieve test. It's how we measure particle fineness in soapstone powder. A 200 mesh means the powder passes through a screen with 200 openings per linear inch. Higher number, finer powder. Simple, right? But here's where it gets interesting. That difference between 300 and 400 mesh? It can make or break your product quality. You'll notice it in everything from texture to final performance.

Matching Mesh to Your Industry It's Not One-Size-Fits-All

For Plastics & Polymers (200-325 mesh)

If you're working with PP or PE compounds, this range is your sweet spot. It blends smoothly without clogging your equipment. We've supplied polymer manufacturers across India for decades and they don't compromise on this spec.

Paints & Coatings (325-400 mesh)

Want that silky, brush-stroke-free finish? You need finer particles. At 325 mesh and above, soapstone powder disperses beautifully. The magic happens when particles are small enough to stay suspended but large enough to provide the perfect matting effect.

Cosmetics & Personal Care (400-500 mesh)

Here's where particle size becomes non-negotiable. Skin-contact products demand ultra-fine talc powder. Anything coarser feels gritty. As a leading soapstone powder supplier in India, we maintain strict controls for cosmetic-grade material. Your reputation depends on it.

Pharmaceuticals (500+ mesh)

Tablet manufacturing requires ultra-fine mesh sizes for proper binding and dissolution rates. It's technical, but critical for pharmaceutical compliance.

Automotive Applications (300-400 mesh)

For anti-blocking masterbatches, this mid-fine range offers the best balance. It prevents polymer sheets from sticking without affecting mechanical properties.

Your 4-Point Selection Checklist

Don't just order based on what someone else uses. Consider these factors:

Final Product Texture – Will customers touch it? See it? That determines how fine you need to go.

Equipment Compatibility – Your grinding mills and mixers have limits. Push too fine, and you'll face processing headaches.

Budget vs. Performance – Finer mesh costs more. Sometimes 300 mesh delivers 95% of what 400 mesh would at significantly lower cost.

Industry Regulations – Especially in pharma and cosmetics, compliance isn't optional.

Why Your Supplier Choice Matters More Than You Think

Here's the thing: consistency matters as much as the mesh number itself. A batch testing at 325 mesh today should test the same next month. That's where experience counts.

At Vasundhara Micron, we've been processing industrial minerals since 1955. Our ISO 9001:2015 certification ensures every shipment meets spec. When sourcing from a soapstone powder supplier in India with 66+ years in business, you're not just buying powder you're buying predictability.

We control the entire process, from our Rajasthan mines to grinding facilities. This means we customize mesh sizes for your application, maintain tight quality controls, and deliver consistency that imports can't match.

Ready to Get Your Mesh Size Right?

Whether you're formulating a new product or troubleshooting an existing one, particle size selection doesn't have to be guesswork. Partner with a soapstone powder supplier in India who understands that behind every mesh specification is a business goal. Because mesh size isn't just a number on a spec sheet. It's the difference between a product that works and one that wows. Get in touch with Vasundhara Micron today and let's find the perfect mesh size for your application.